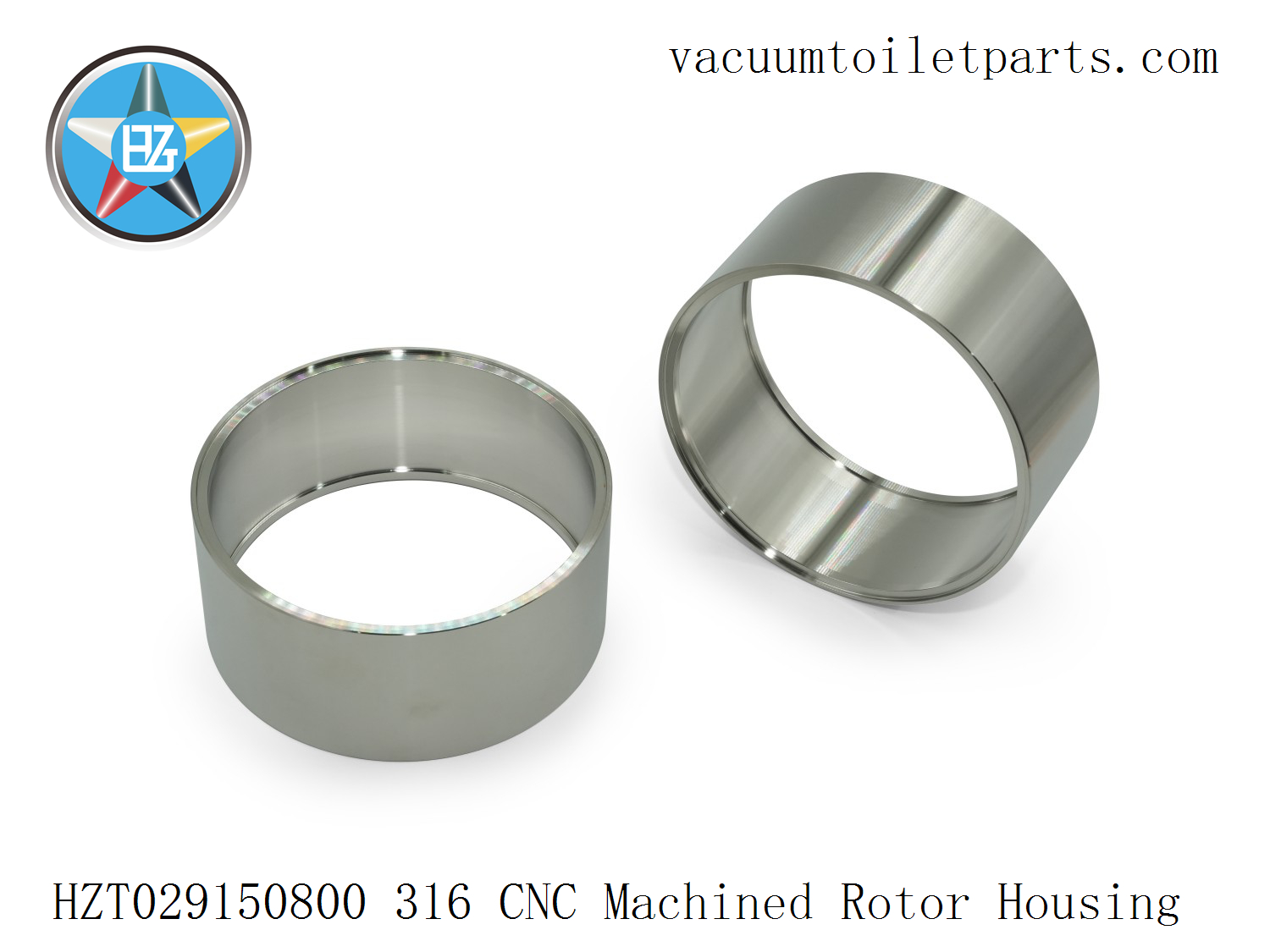

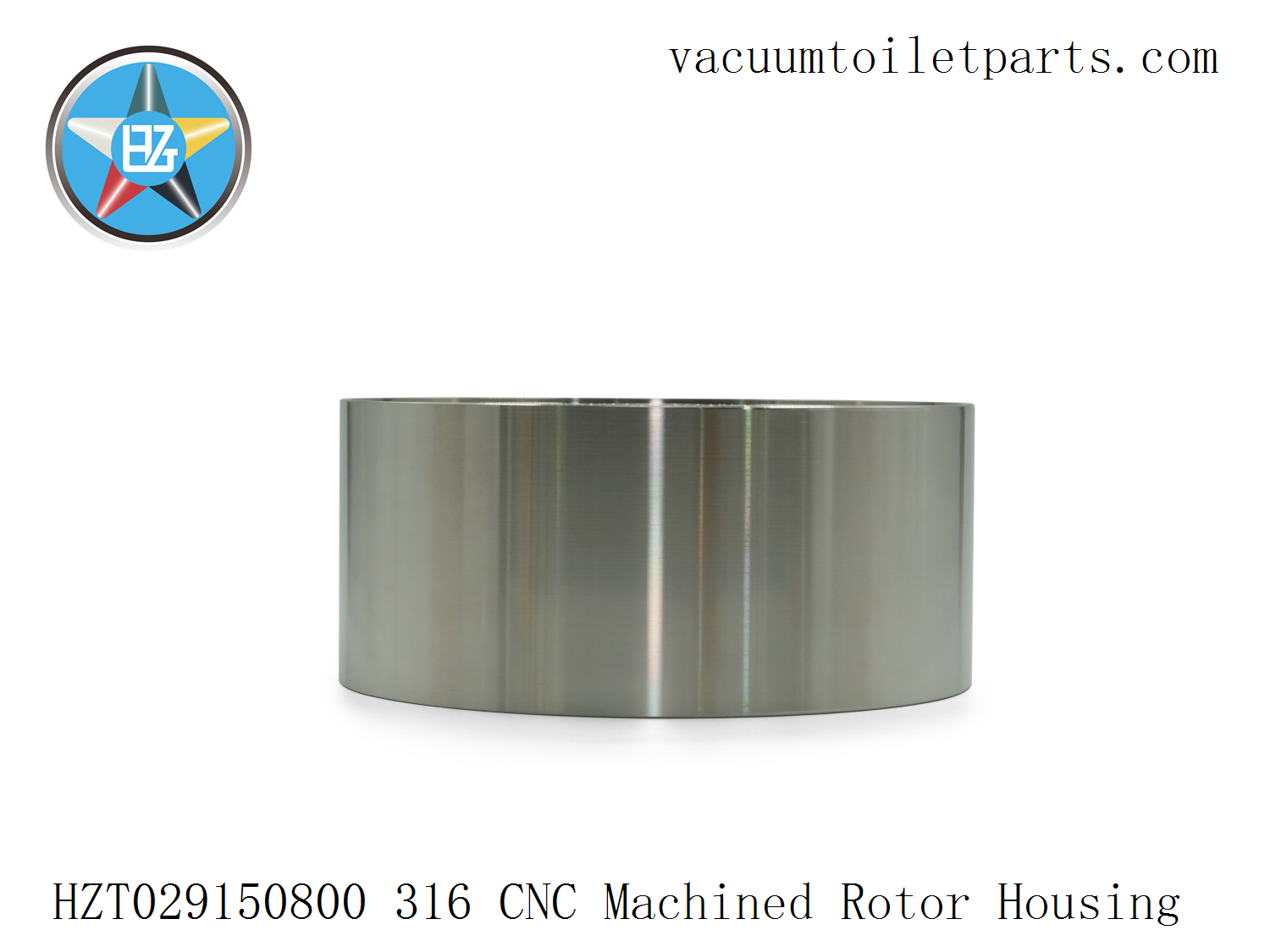

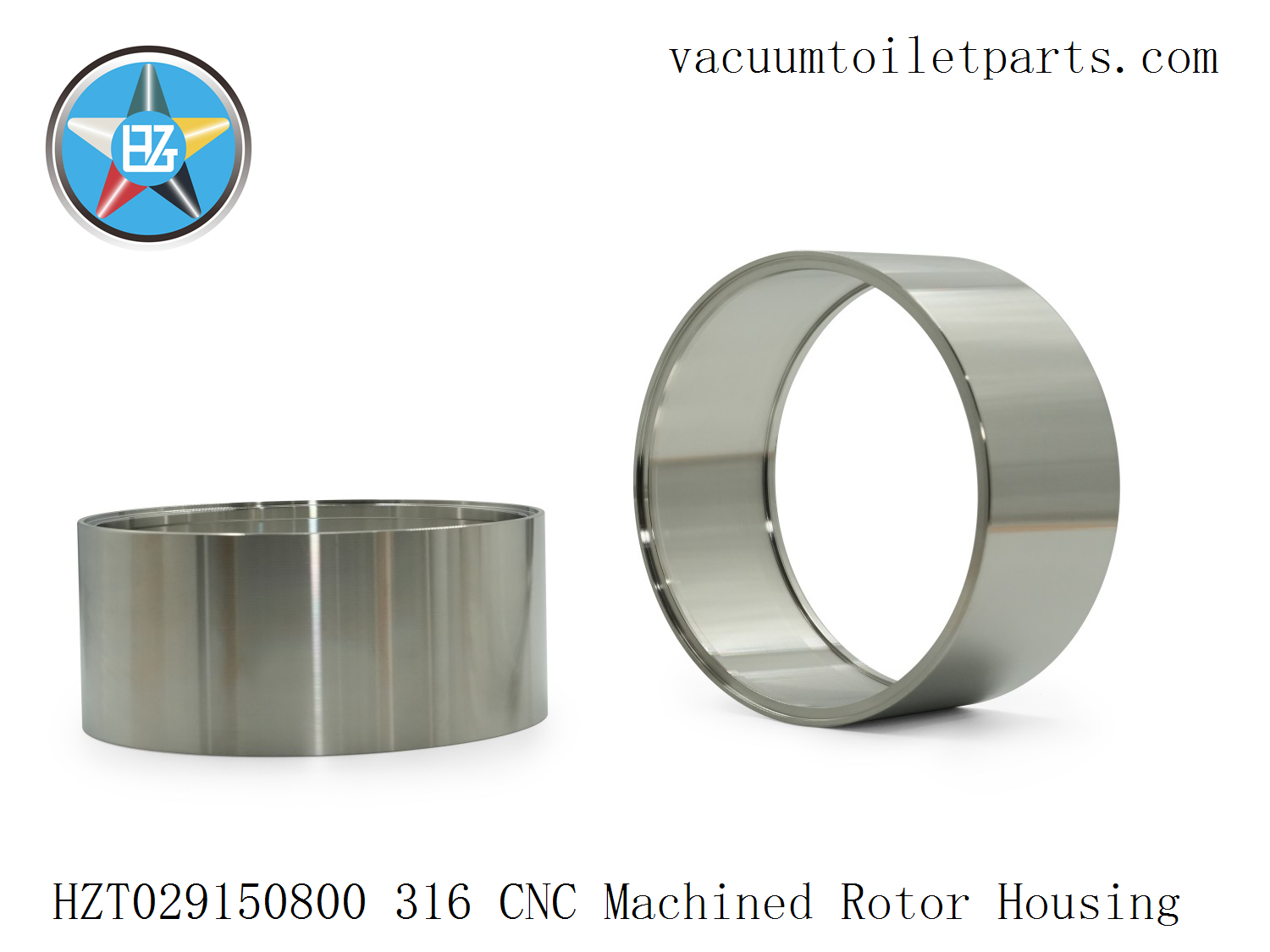

The HZT029150800 rotor housing is a key component in the HZT 15MBD marine vacuum sewage pump system. Its primary function is to create a vacuum chamber and protect the rotor (HZT029150701), ensuring stable rotation under high negative pressure and fluid flow conditions.

This component is precision-turned from seamless 316 stainless steel tubing through CNC machining. Its smooth interior and high coaxiality ensure the system’s vacuum performance and reliability.

I. Structure and Design Features

* Monolithic Cylindrical Structure

The rotor housing is machined from a seamless tube, eliminating welds to prevent leakage and deformation, ensuring high vacuum tightness.

* Precision Inner Bore

The inner bore undergoes CNC precision turning and electrolytic treatment, achieving a surface roughness of Ra0.8, ensuring smooth rotor operation and zero eccentric vibration.

* High Concentricity Design

Coaxial assembly with the rotor (HZT029150701) and end flange (HZT029150601) ensures stable operation after dynamic balancing (G2.5).

* Surface Finish

The brushed finish provides corrosion resistance and enhances the appearance, reflecting the HZT brand’s high-quality manufacturing process.

II. Manufacturing Process

1. Material: 316 stainless steel (Grade A4)

Excellent resistance to chloride ion corrosion, suitable for long-term use in marine and humid environments;

2. Processing: CNC Precision Turning

Molded from a single piece of seamless stainless steel pipe, the tube is clamped and formed in one go, ensuring precise inner and outer diameter coaxiality;

3. Surface Treatment: Brushed finish

Enhanced corrosion and stain resistance, preventing the adhesion of impurities from wastewater;

4. Inspection: Dimensional inspection + coaxiality inspection + inner wall roughness inspection

Ensures assembly accuracy meets HZT internal vacuum system standards.

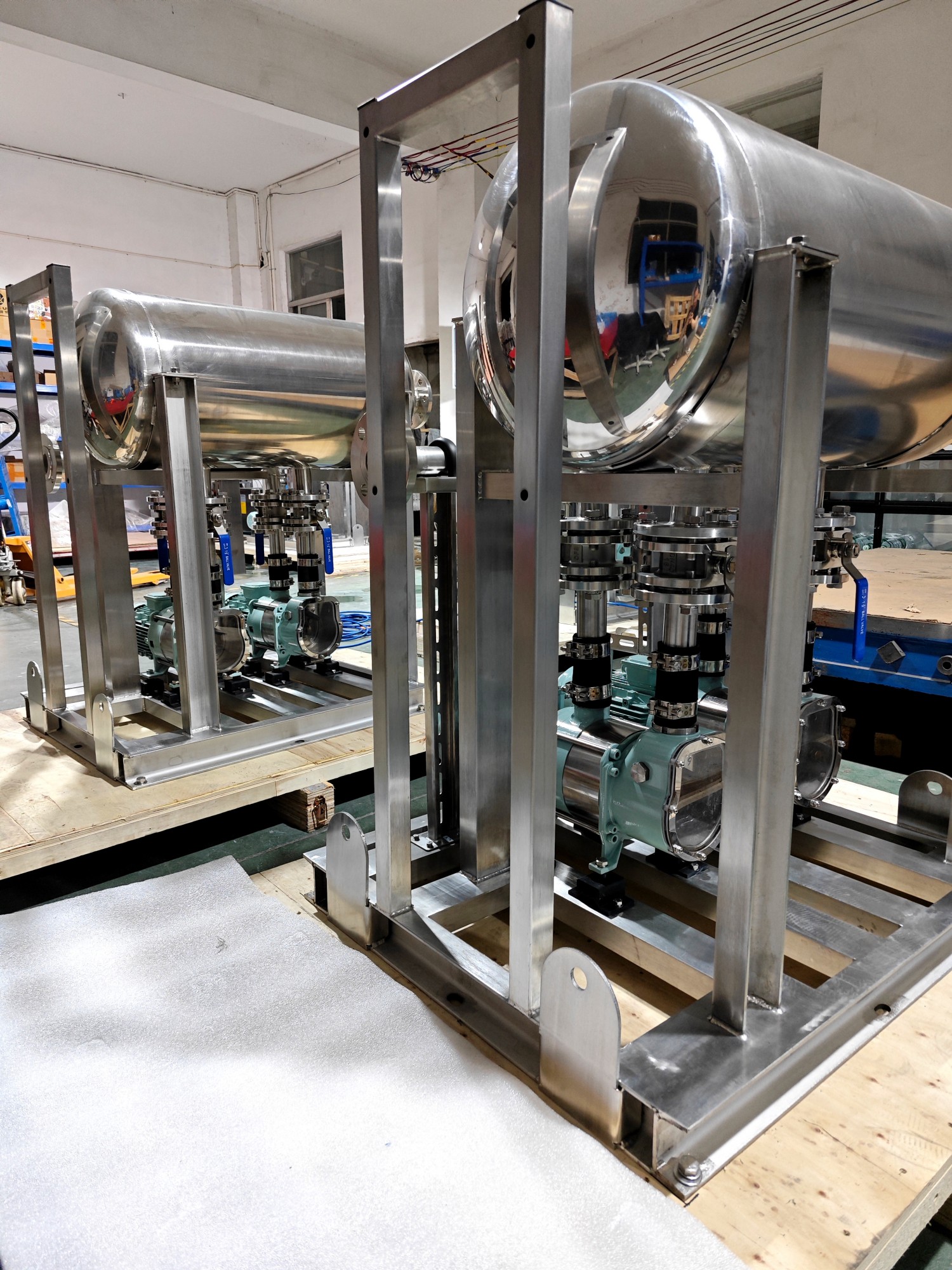

III. System Function and Assembly Relationship

The rotor housing (HZT029150800) serves as the central pressure-bearing chamber of the pump body. Its front end is connected to the cutting unit via an end flange (HZT029150601), housing the rotor (HZT029150701). Its rear end connects to the pressure chamber (HZT029150901), forming a single-piece vacuum flow path for suction, shearing, rotation, and discharge.

During operation, the rotor housing:

* Supports high-speed rotor rotation and ensures stable clearance within the impeller cavity;

* Withstands gas-liquid mixed pressure and mechanical vibration;

* Provides a sealed chamber to prevent leakage and external contamination;

* Reduces energy consumption and turbulence through a smooth flow path.

IV. Performance and Application

* High-precision structure: Ensures stable system dynamic balance;

* Excellent corrosion and rust resistance**;

* Strong assembly compatibility: 25MBAs in the same series share the same structure (different dimensions), allowing for system modification or upgrades;

* Applications:

🚢 Marine vacuum sewage and blackwater systems

⚙️ Vacuum toilets and domestic sewage installations

🧰 Port and offshore wastewater systems

V. Assistance technique et fourniture

HZT fournit un équipement complet, une conception de système et des services accessoires :

* Solutions complètes pour les pompes à vide marines et les stations de pompage sous vide des eaux usées

* Système OEM et soutien aux chantiers navals

* Approvisionnement rapide en pièces détachées et services de réparation

📧 Courriel de l'assistance technique : SJDT1199@gmail.com

🌐 Site web officiel : www.vacuumtoiletparts.com

1. HZT029151001 - Base de la valve à clapet

2. HZT037302200 - Disque de soupape à clapet

3. HZT029151003 - Plaque de pression

4. HZT029150310 - Couvercle de la chambre d'aspiration

5. HZT037219210 - Joint torique

6. HZT029150320 - Chambre d'aspiration

7. HZT020202900 - Bouchon d'étanchéité à six pans creux

8. HZT029151900 - Contre-écrou

9. HZT029150400 - Lame rotative

10. HZT029150500 - Lame fixe

11. HZT029152401 - Boulon hexagonal demi-fileté avec rondelle élastique, M10x170 mm

12. HZT029150601 - Bride d'extrémité

13. HZT029150701 - Rotor (roue)

14. HZT029150800 - Boîtier de rotor

15. HZT029151800 - Douille d'écartement

16. HZT038201500 - Joint d'arbre

17. HZT034507420 - Collier de serrage

18. HZT034507500 - Tuyau

19. HZT029150391 - Bride d'extrémité de joint d'arbre

20. HZT029150901 - Chambre de pression (chambre de décharge)

21. HZT029150310-02 - Couvercle d'aspiration (plaque métallique)

22. HZT029150450 - Assemblage de lames

23. HZT/- - Moteur - 2.2KW - Moteur marin

24. HZT029015001 - Pompe à vide 15MBD

25. HZT023280061 - Siège de soupape à clapet

26. HZT037302100 - Disque de soupape à clapet

27. HZT023280091 - Plaque de pression

28. HZT023280050 - Couvercle de la chambre d'aspiration

29. HZT037219260 - Joint torique

30. HZT023280070 - Fixation de bride

31. HZT023280080 - Bride

32. HZT023280040 - Chambre d'aspiration

33. HZT020202900 - Bouchon

34. HZT020203100 - Lame rotative

35. HZT020203100 - Lame fixe

36. HZT021201000 - Porte-lame

37. HZT036202010 - Boulon hexagonal à demi-filet (avec rondelle élastique) M12x220

38. HZT023200210 - Plaque d'extrémité de la chambre d'aspiration

39. HZT023219000 - Boîtier de rotor

40. HZT021265401 - Rotor (Impeller)

41. HZT021217000 - Bouchon RG 3/8

42. HZT023219000 - Chambre de pression (chambre d'évacuation de l'eau)

43. HZT023260400 - Douille d'écartement

44. HZT038218900 - Joint d'arbre

45. HZT023280030 - Bride d'étanchéité d'arbre

46. HZT023280050-02 - Couvercle de la chambre d'aspiration (plaque métallique)

47. HZT/- - Moteur - 3.0kW - Moteur marin

48. HZT023280010 - Pompe à vide 25MBA

6541458, 5900200, 6558400147, 5957600, 5980801, 6541673, 5979000, 5435181, 5451480, 6543469, 6543521, 5980914, 5981000, 6545873, 6545872, 6541672, 5979500, 5979600, 6542601, 6542586, 6541675, 5775500, 5973401, 6545363, 6543035, 5959902, 6542998, 6545393, 6541552, 5437623, 6540972, 6540973, 6543036, 5821700, 5433594, 6542305, 6545041, 5821000, 6542997, 6547089, 6547327, 6545537, 5490590, 5490587, 5450072, 5490580, 6541525, 6546852, 6545903, 6541709, 6541708, 6546255, 6542549, 6542827, 6543101, 6545725, 5437598, 5430612, 6541200, 5442101, 5824900, 6541003, 5980802, 6542958, 5435169, 6545052, 65433072, 5779210, 5780000, 5779400, 5435269, 6543003, 70701001, 5774002, 5774000, 5900204, 5435015, 5774901, 6542981, 6545051, 6542402, 6543002, 5481004, 6543072, 5445001, 6545828, 6540969, 5437666, 5913502, 5430595, 5979312, 6545901, 5490548, 6542451, 6542434, 6543229, 5470214, 6542983, 6542982, 5433215, 5432548