1. Обзор продукции

The HZT023280061 flap valve seat is a key supporting component of the 25MBA vacuum pump suction valve assembly. Located below the suction chamber (HZT023280040), it provides a reference and sealing surface for the flap valve disc (HZT037302100). This part is precision-machined from 316 stainless steel, offering both corrosion resistance and a high-precision sealing surface. During valve operation, the seat’s conical sealing surface dynamically cooperates with the disc to effectively control unidirectional flow in the suction and discharge channels, preventing backflow and improving system pumping efficiency.

2. Structure & Features

1. Integrally Precision-Machinery

*Made from solid 316 bar stock, formed through a combination of roughing and finishing processes. The valve port, sealing step, and guide arc are positioned in a single process.

* Ensures the disc’s seating flatness and coaxiality with the valve core center.

2. Integrated Sealing Reference and Diversion Chamber

* The upper end of the base serves as the valve disc’s opening and closing reference, while the lower end serves as the transition surface to the diversion chamber. Smoothly rounded corners prevent turbulence and cavitation.

3. Precision Threaded Assembly Interface

* The lower end is threaded and secured with a flange fastener (HZT023280070), ensuring secure assembly and repeatable disassembly.

* A precision guide section is provided in the threaded engagement area to ensure reliable positioning and prevent stress concentration on the pump body wall.

4. O-Ring Seal

* An O-ring (HZT037219280) seal groove is located below the valve seat, forming a static seal with the suction chamber wall to prevent negative pressure leakage.

5. Easy Maintenance

* The entire valve assembly can be disassembled and assembled in situ; the disc and seat can be replaced without disassembling the pump assembly, facilitating quick maintenance.

3. Material & Manufacturing

* Material: 316 stainless steel (or 316L)

* Manufacturing Process: CNC turning → fine boring → chamfering and deburring → sealing surface grinding → cleaning and corrosion protection

* Surface Requirements:

* Sealing surface roughness Ra ≤ 0.8 μm

* Deburring and gauge calibration after thread machining

* Inspection Standard: Three-stage verification: First-article, in-process, and final inspection, performed in accordance with GJB9001C process control requirements.

4. Assembly Relationship

* Together with the valve disc (HZT037302100), pressure plate (HZT023280091), and O-ring (HZT023712962), this component forms a check valve assembly. * The lower end is threaded with a flange fastener (HZT023280070) and assembled into the suction chamber (HZT023280040).

* The outer flange stop of the flange fastener forms a metal locating datum with the end face of the suction chamber. The specified torque should be applied during assembly to prevent axial movement of the valve seat.

* Valve assembly sequence:

O-ring → flap valve seat → disc → pressure plate → tighten flange fastener threads.

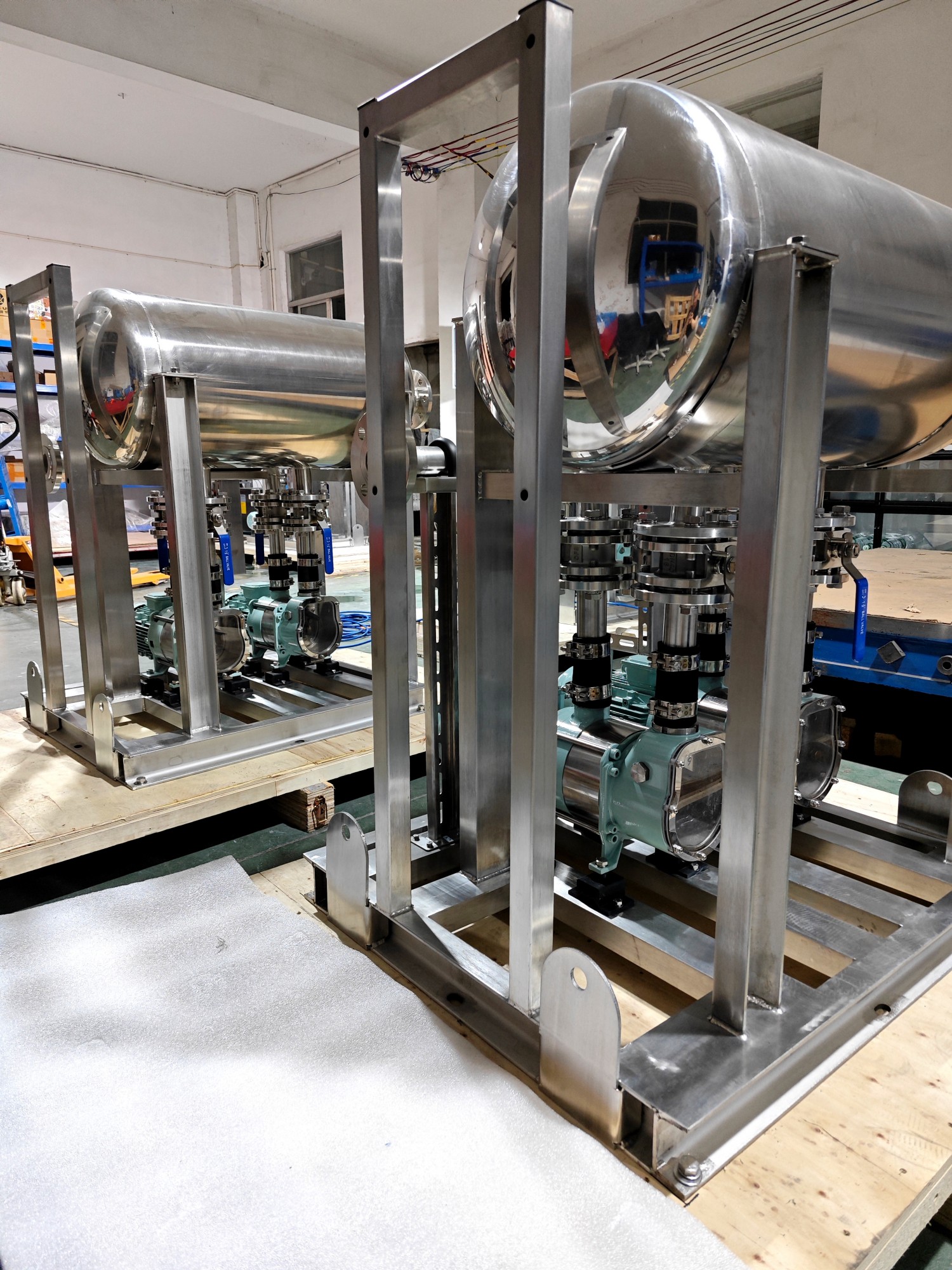

5. Приложения

* Vacuum sewage systems for ships and yachts

* Sanitation and sewage treatment equipment for offshore platforms

* Industrial vacuum conveying and low-pulsation liquid pumping systems

This component operates in environments with high humidity, high salt spray, and particulate matter for extended periods, placing extremely high demands on material corrosion resistance and sealing reliability.

6. Technical Data (Typical Values) | Technical Data *(For Reference)*

| Item | Parameter | Description |

| —– | ———- | —— |

| Material | 316 Stainless Steel | Turned Part |

| Surface Roughness | Ra ≤ 0.8 μm | Sealing Surface |

| Flatness | ≤ 0.05 mm | Disc Contact Surface |

| Assembly Torque | 18–25 N·m | Flange Fasteners |

| Operating Media | Black Water/Solid-Containing Wastewater | Marine Vacuum System |

| Temperature Range | 0–80°C | Normal Operating Environment |

7. Inspection & Maintenance | Inspection & Maintenance

* Each batch undergoes dimensional and visual inspection according to the Q/WHJT–25MBA–INS inspection procedures;

* The valve seat sealing surface must be inspected under optical magnification to ensure there are no indentations or scratches;

* Inspection is recommended every 3000 hours. After operation, check the valve disc for proper opening and closing. If grooves or rust are present, repair or replace it after grinding.

8. Техническая поддержка и снабжение

HZT предоставляет комплексное оборудование, проектирование систем и услуги по подбору комплектующих:

* Комплексные решения для морских вакуумных насосов и канализационных вакуумных насосных станций

* Система OEM и поддержка верфи

* Быстрая поставка запчастей и ремонт

📧 Электронная почта технической поддержки: SJDT1199@gmail.com

🌐 Официальный сайт: www.vacuumtoiletparts.com

1. HZT029151001 - Седло клапана заслонки

2. HZT037302200 - диск заслонки

3. HZT029151003 - нажимной диск

4. HZT029150310 - Крышка всасывающей камеры

5. HZT037219210 - уплотнительное кольцо

6. HZT029150320 - Всасывающая камера

7. HZT020202900 - Шестигранное торцевое уплотнение

8. HZT029151900 - контргайка

9. HZT029150400 - Вращающийся нож

10. HZT029150500 - Стационарный нож

11. HZT029152401 - Болт с шестигранной полурезьбой и пружинной шайбой (M10x170)

12. HZT029150601 - Торцевой фланец

13. HZT029150701 - Ротор (крыльчатка)

14. HZT029150800 - Корпус ротора

15. HZT029151800 - Проставка

16. HZT038201500 - Уплотнение вала

17. HZT034507420 - Хомут шланга

18. HZT034507500 - Шланг

19. HZT029150391 - Фланец уплотнения вала

20. HZT029150901 - Камера давления (камера сброса воды)

21. HZT029150310-02 - Крышка всасывания (металлическая пластина)

22. HZT029150450 - Фреза в сборе

23. HZT/- - Двигатель - 2,2 кВт - Морской двигатель

24. HZT029015001 - Вакуумный насос 15MBD

25. HZT023280061 - Седло клапана заслонки

26. HZT037302100 - Диск клапана заслонки

27. HZT023280091 - нажимной диск

28. HZT023280050 - Крышка всасывающей камеры

29. HZT037219260 - уплотнительное кольцо

30. HZT023280070 - Крепление фланца

31. HZT023280080 - Фланец

32. HZT023280040 - Камера всасывания

33. HZT020202900 - Вилка

34. HZT020203100 - Вращающийся нож

35. HZT020203100 - Стационарный нож

36. HZT021201000 - Держатель лезвия

37. HZT036202010 - Болт с шестигранной полурезьбой (с пружинной шайбой) M12x220

38. HZT023200210 - Торцевая пластина камеры всасывания

39. HZT023219000 - Корпус ротора

40. HZT021265401 - Ротор (рабочее колесо)

41. HZT021217000 - Заглушка RG 3/8”

42. HZT023219000 - Камера давления (разгрузочная камера)

43. HZT023260400 - Изолирующая втулка

44. HZT038218900 - Уплотнение вала

45. HZT023280030 - Фланец уплотнения вала

46. HZT023280050-02 - Крышка всасывающей камеры (металлический лист)

47. HZT/- - Двигатель - 3,0 кВт - Судовой двигатель

48. HZT023280010 - Вакуумный насос 25 MBA

6541458, 5900200, 6558400147, 5957600, 5980801, 6541673, 5979000, 5435181, 5451480, 6543469, 6543521, 5980914, 5981000, 6545873, 6545872, 6541672, 5979500, 5979600, 6542601, 6542586, 6541675, 5775500, 5973401, 6545363, 6543035, 5959902, 6542998, 6545393, 6541552, 5437623, 6540972, 6540973, 6543036, 5821700, 5433594, 6542305, 6545041, 5821000, 6542997, 6547089, 6547327, 6545537, 5490590, 5490587, 5450072, 5490580, 6541525, 6546852, 6545903, 6541709, 6541708, 6546255, 6542549, 6542827, 6543101, 6545725, 5437598, 5430612, 6541200, 5442101, 5824900, 6541003, 5980802, 6542958, 5435169, 6545052, 65433072, 5779210, 5780000, 5779400, 5435269, 6543003, 70701001, 5774002, 5774000, 5900204, 5435015, 5774901, 6542981, 6545051, 6542402, 6543002, 5481004, 6543072, 5445001, 6545828, 6540969, 5437666, 5913502, 5430595, 5979312, 6545901, 5490548, 6542451, 6542434, 6543229, 5470214, 6542983, 6542982, 5433215, 5432548