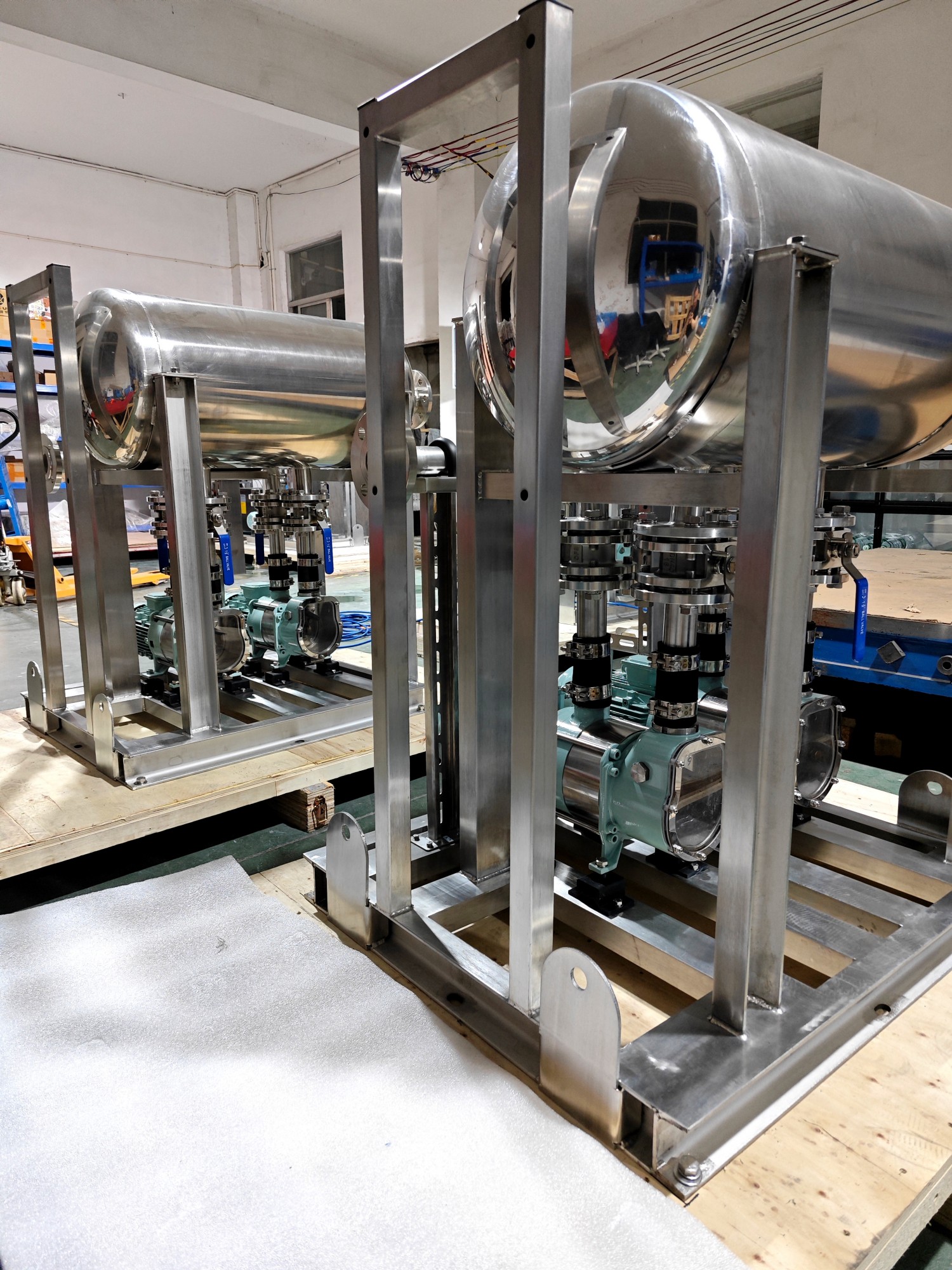

The T029150450 knife assembly is the core shredding component of the HZT 15MBD Marine Vacuum Sewage Pump System. It consists of two parts:

* Rotating knife (HZT029150400) – mounted on the motor output shaft;

* Fixed knife (HZT029150500) – fixed to the end flange (HZT029150601).

Together, these two components form a highly efficient shredding system, designed to cut and shred ship sewage, black water, and debris, preventing blockage in the vacuum pump and piping, and ensuring long-term, stable system operation.

1. Advantages of structure and manufacturing process

* High-strength 17-4PH (630) stainless steel material:

The blade set is made of a solid 17-4PH stainless steel forging blank, which has been solution-treated and aging-treated (HRC 40-45), and has both high hardness and impact toughness;

* 5-Axis CNC Precision Machining:

The blade surface and the mounting reference surface are completed in one step by five-axis linkage machining, ensuring the matching accuracy and dynamic balance performance of the dynamic and static blades;

* Double-layer heat treatment control:

The hardness gradient of the surface and core is optimized to improve the wear resistance and prevent chipping;

* Mirror blade and anti-corrosion passivation treatment:

Improve cutting efficiency while reducing the adhesion of sewage impurities and biofouling deposition.

II. Function and System Principle

The HZT029150450 blade assembly is located inside the pump head inlet, mounted between the suction chamber (HZT029150320) and the end flange (HZT029150601):

* The motor drives the rotating blades (HZT029150400) to rotate at high speed;

* The fixed blades (HZT029150500) form a shearing mechanism;

* Debris is crushed and wastewater is homogenized within a micro-shear clearance;

* The crushed fluid enters the pump chamber and is drawn out by the impeller (HZT029150701).

This design maintains a stable vacuum system flow while effectively preventing clogging and pump damage.

III. Engineering Features and Technical Advantages

* 🔩 High Shearing Efficiency: The dynamic and static blades work together to continuously shred fibers, hair, plastic, tissues, and other household debris.

* ⚙️ Dynamically Balanced Design: Five-axis machining ensures symmetrical quality of the rotating blades, reducing vibration and noise.

* 💧 Vacuum Compatibility: The fully sealed structure is suitable for vacuum sewage treatment without affecting the system’s vacuum level.

* 🛠️ Maintainability: The blade assembly is a consumable part and can be replaced independently, improving operation and maintenance efficiency.

* 🚢 Corrosion Resistance: 17-4PH alloy material combined with heat treatment process provides long-term resistance to sewage, salt spray, and acid and alkaline media.

IV. Series Adaptation and Compatibility

* Applicable to: HZT 15MBD Marine Vacuum Sewage Pump

* Similar in structure to the 25MBA series, but with different dimensions and connections, not directly interchangeable.

* Strong replacement and repair compatibility: Can be used as a standard replacement part for the 15MBD pump head.

* Mounting Interface: Assembles with HZT029150320 (suction chamber) and HZT029150601 (end flange).

V. Industry Application Scenarios

The HZT029150450 blade set is widely used in:

* 🚢 Marine Sewage and Blackwater Vacuum Collection Systems

* ⚙️ Vacuum Toilet and Sewage Discharge Systems

* 🛳️ Offshore Wastewater Treatment Systems

* 🧰 Port and Marine Sanitation Units

Its durability, anti-clogging performance, and cutting efficiency make it a core component for vacuum sewage treatment equipment.

VI. Техническая поддержка и снабжение

HZT предоставляет комплексное оборудование, проектирование систем и услуги по подбору комплектующих:

* Комплексные решения для морских вакуумных насосов и канализационных вакуумных насосных станций

* Система OEM и поддержка верфи

* Быстрая поставка запчастей и услуги по ремонту

📧 Электронная почта технической поддержки: SJDT1199@gmail.com

🌐 Официальный сайт: www.vacuumtoiletparts.com

1. HZT029151001 - Седло клапана заслонки

2. HZT037302200 - диск заслонки

3. HZT029151003 - нажимной диск

4. HZT029150310 - Крышка всасывающей камеры

5. HZT037219210 - уплотнительное кольцо

6. HZT029150320 - Всасывающая камера

7. HZT020202900 - Шестигранное торцевое уплотнение

8. HZT029151900 - контргайка

9. HZT029150400 - Вращающийся нож

10. HZT029150500 - Стационарный нож

11. HZT029152401 - Болт с шестигранной полурезьбой и пружинной шайбой (M10x170)

12. HZT029150601 - Торцевой фланец

13. HZT029150701 - Ротор (крыльчатка)

14. HZT029150800 - Корпус ротора

15. HZT029151800 - Проставка

16. HZT038201500 - Уплотнение вала

17. HZT034507420 - Хомут шланга

18. HZT034507500 - Шланг

19. HZT029150391 - Фланец уплотнения вала

20. HZT029150901 - Камера давления (камера сброса воды)

21. HZT029150310-02 - Крышка всасывания (металлическая пластина)

22. HZT029150450 - Фреза в сборе

23. HZT/- - Двигатель - 2,2 кВт - Морской двигатель

24. HZT029015001 - Вакуумный насос 15MBD

25. HZT023280061 - Седло клапана заслонки

26. HZT037302100 - Диск клапана заслонки

27. HZT023280091 - нажимной диск

28. HZT023280050 - Крышка всасывающей камеры

29. HZT037219260 - уплотнительное кольцо

30. HZT023280070 - Крепление фланца

31. HZT023280080 - Фланец

32. HZT023280040 - Камера всасывания

33. HZT020202900 - Вилка

34. HZT020203100 - Вращающийся нож

35. HZT020203100 - Стационарный нож

36. HZT021201000 - Держатель лезвия

37. HZT036202010 - Болт с шестигранной полурезьбой (с пружинной шайбой) M12x220

38. HZT023200210 - Торцевая пластина камеры всасывания

39. HZT023219000 - Корпус ротора

40. HZT021265401 - Ротор (рабочее колесо)

41. HZT021217000 - Заглушка RG 3/8”

42. HZT023219000 - Камера давления (разгрузочная камера)

43. HZT023260400 - Изолирующая втулка

44. HZT038218900 - Уплотнение вала

45. HZT023280030 - Фланец уплотнения вала

46. HZT023280050-02 - Крышка всасывающей камеры (металлический лист)

47. HZT/- - Двигатель - 3,0 кВт - Судовой двигатель

48. HZT023280010 - Вакуумный насос 25 MBA

6541458, 5900200, 6558400147, 5957600, 5980801, 6541673, 5979000, 5435181, 5451480, 6543469, 6543521, 5980914, 5981000, 6545873, 6545872, 6541672, 5979500, 5979600, 6542601, 6542586, 6541675, 5775500, 5973401, 6545363, 6543035, 5959902, 6542998, 6545393, 6541552, 5437623, 6540972, 6540973, 6543036, 5821700, 5433594, 6542305, 6545041, 5821000, 6542997, 6547089, 6547327, 6545537, 5490590, 5490587, 5450072, 5490580, 6541525, 6546852, 6545903, 6541709, 6541708, 6546255, 6542549, 6542827, 6543101, 6545725, 5437598, 5430612, 6541200, 5442101, 5824900, 6541003, 5980802, 6542958, 5435169, 6545052, 65433072, 5779210, 5780000, 5779400, 5435269, 6543003, 70701001, 5774002, 5774000, 5900204, 5435015, 5774901, 6542981, 6545051, 6542402, 6543002, 5481004, 6543072, 5445001, 6545828, 6540969, 5437666, 5913502, 5430595, 5979312, 6545901, 5490548, 6542451, 6542434, 6543229, 5470214, 6542983, 6542982, 5433215, 5432548