The HZT020203100 blade assembly is the core pulverizing unit of the HZT 25MBA Marine Vacuum Discharge Pump. It consists of a rotating knife and a stationary knife. Both are made of 17-4PH (630) precipitation-hardened stainless steel with a hardness controlled in the HRC 40–45 range. They combine high strength, wear resistance, and corrosion resistance to meet the demanding working conditions of high humidity, salt spray, and solid impurities at sea.

It shares a similar structural concept with the 15MBD series, but its geometric dimensions, mounting interface, and working clearance are completely different, making it not interchangeable with the 15MBD. This assembly is optimized for the higher flow rate, higher speed, and greater torque of the 25MBA, making it suitable for multi-compartment and heavy-duty vacuum collection/discharge systems.

1. Functional Positioning: Efficient shredding, ensuring unobstructed vacuum flow

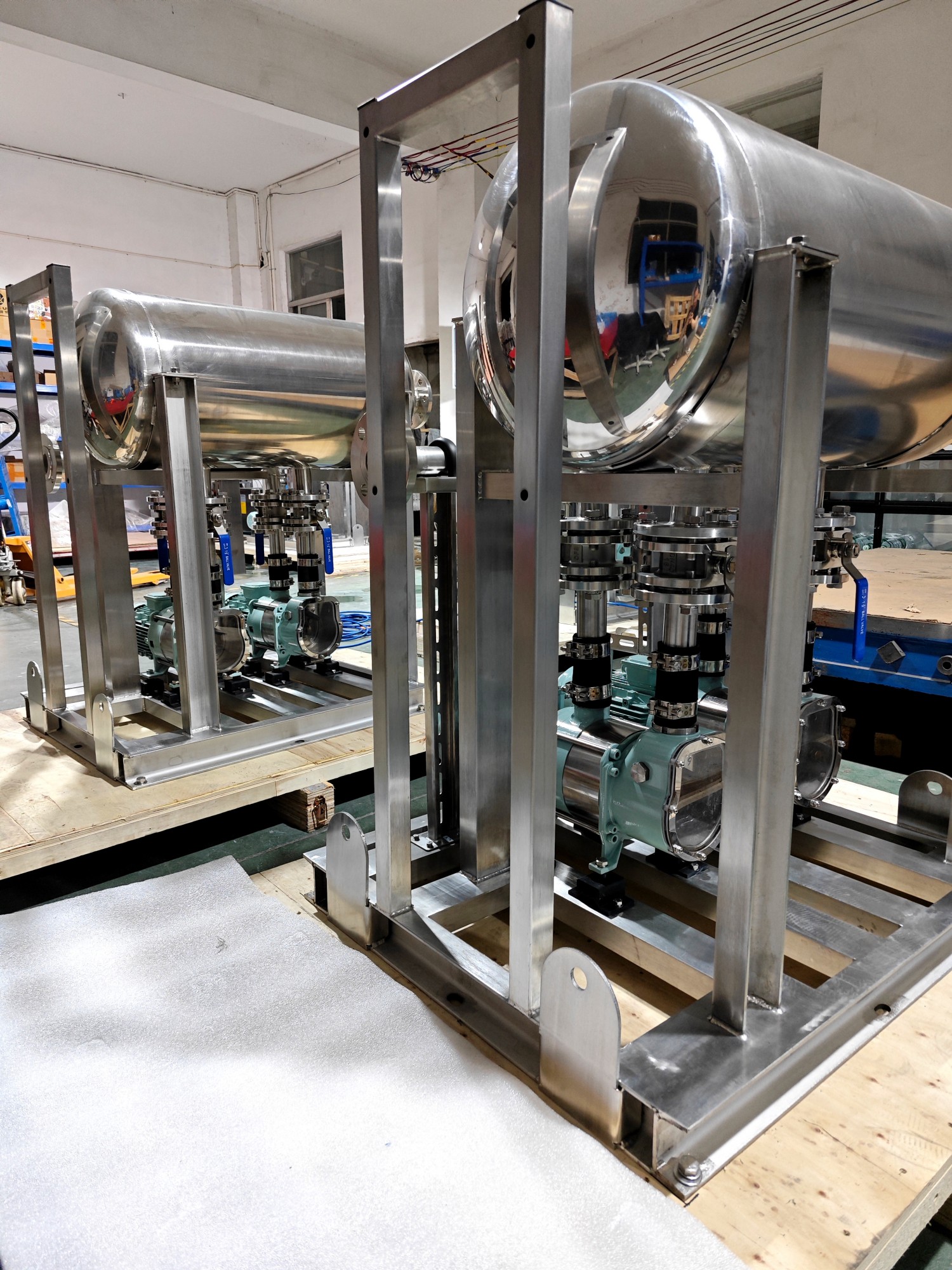

The blade assembly forms a high-efficiency shearing zone between the pump head inlet and the front end of the impeller, shredding paper towels, fibers, films, soft plastics, food scraps, and other materials entering the system. This significantly reduces the risk of blockage and ensures continuous and stable vacuum collection, delivery, and discharge. This assembly, along with the end plate (HZT023200210 End Plate Suct. Chamber), end flange (HZT023280030 Flange), rotor (HZT021265401 Rotor), and rotor housing (HZT023219000 Rotor Housing), form a complete pump head operating unit.

2. Key Structural Features: Designed for the heavy-duty operation of the 25MBA pump.

* Dual Blade Synergy: Rotating blades provide high-speed shearing, while fixed blades provide stable support and guidance, maintaining a consistent shear gap** and cutting angle.

* High Torque: Matched to the higher speed and torque of the 25MBA main engine, this enhances handling of entangled and tough debris. * Geometry and Interface: The 25MBA uses a dedicated cutterhead geometry and mounting hole spacing/shaft end interface, which is not interchangeable with the 15MBD to prevent mis-installation.

* Corrosion and Fatigue Resistance: The material and structure combine resistance to pitting, entanglement, and fatigue fracture, making it suitable for long-term continuous operation.

III. Materials and Performance (Application-Oriented Description)

* Base Material: 17-4PH (630) stainless steel, offering excellent combined strength and corrosion resistance, suitable for offshore/shore-based vacuum systems.

* Hardness: HRC 40–45, providing balanced sharpness, wear resistance, and chipping resistance.

* Surface and Edge: The blade geometry is carefully controlled, resulting in high shear efficiency and sufficient impurity refinement, facilitating downstream pipeline transportation. * Stability: Together with the shaft seal (HZT038281900), distance sleeve (HZT023260400), and shaft seal end flange (HZT023280030), this system forms a reliable axial positioning and sealing system, reducing vibration and the risk of fluid cross-contamination.

IV. Applicable Scenarios and System Expansion

* Ships and Yachts: Vacuum sanitation/discharge systems onboard ro-ro passenger ships, engineering vessels, and yachts.

* Offshore Engineering and Ports: Vacuum discharge and centralized collection systems on offshore platforms and docks.

* Land-Based Vacuum Toilets: Land-Based Vacuum Toilet/Collection systems in villa communities, campsites, tourist areas, and at train stations/airports.

* Upgrades and Replacements: Suitable for routine maintenance, refurbishment, and spare parts replacement of the HZT 25MBA main engine. It can also serve as a reference for retrofit selection of EVAC/JETS systems (subject to interface compatibility).

V. Operation, Maintenance, and Model Selection Recommendations

* Model Selection: Only compatible with the HZT 25MBA; if a 15MBD blade assembly is required, select the corresponding model to avoid interchangeability.

* Maintenance: Calculate maintenance intervals based on media complexity and operating time. If you notice decreased cutting efficiency or abnormal motor load, check blade wear and clearance.

* Supporting Equipment: It is recommended to perform maintenance in conjunction with the end flange, end plate, shaft seal, and O-ring seal (HZT037219200 / HZT037221602) to restore overall pump head performance.

VI. Техническая поддержка и снабжение

HZT предоставляет комплексное оборудование, проектирование систем и услуги по подбору комплектующих:

* Комплексные решения для морских вакуумных насосов и канализационных вакуумных насосных станций

* Система OEM и поддержка верфи

* Быстрая поставка запчастей и услуги по ремонту

📧 Электронная почта технической поддержки: SJDT1199@gmail.com

🌐 Официальный сайт: www.vacuumtoiletparts.com

1. HZT029151001 - Седло клапана заслонки

2. HZT037302200 - диск заслонки

3. HZT029151003 - нажимной диск

4. HZT029150310 - Крышка всасывающей камеры

5. HZT037219210 - уплотнительное кольцо

6. HZT029150320 - Всасывающая камера

7. HZT020202900 - Шестигранное торцевое уплотнение

8. HZT029151900 - контргайка

9. HZT029150400 - Вращающийся нож

10. HZT029150500 - Стационарный нож

11. HZT029152401 - Болт с шестигранной полурезьбой и пружинной шайбой (M10x170)

12. HZT029150601 - Торцевой фланец

13. HZT029150701 - Ротор (крыльчатка)

14. HZT029150800 - Корпус ротора

15. HZT029151800 - Проставка

16. HZT038201500 - Уплотнение вала

17. HZT034507420 - Хомут шланга

18. HZT034507500 - Шланг

19. HZT029150391 - Фланец уплотнения вала

20. HZT029150901 - Камера давления (камера сброса воды)

21. HZT029150310-02 - Крышка всасывания (металлическая пластина)

22. HZT029150450 - Фреза в сборе

23. HZT/- - Двигатель - 2,2 кВт - Морской двигатель

24. HZT029015001 - Вакуумный насос 15MBD

25. HZT023280061 - Седло клапана заслонки

26. HZT037302100 - Диск клапана заслонки

27. HZT023280091 - нажимной диск

28. HZT023280050 - Крышка всасывающей камеры

29. HZT037219260 - уплотнительное кольцо

30. HZT023280070 - Крепление фланца

31. HZT023280080 - Фланец

32. HZT023280040 - Камера всасывания

33. HZT020202900 - Вилка

34. HZT020203100 - Вращающийся нож

35. HZT020203100 - Стационарный нож

36. HZT021201000 - Держатель лезвия

37. HZT036202010 - Болт с шестигранной полурезьбой (с пружинной шайбой) M12x220

38. HZT023200210 - Торцевая пластина камеры всасывания

39. HZT023219000 - Корпус ротора

40. HZT021265401 - Ротор (рабочее колесо)

41. HZT021217000 - Заглушка RG 3/8”

42. HZT023219000 - Камера давления (разгрузочная камера)

43. HZT023260400 - Изолирующая втулка

44. HZT038218900 - Уплотнение вала

45. HZT023280030 - Фланец уплотнения вала

46. HZT023280050-02 - Крышка всасывающей камеры (металлический лист)

47. HZT/- - Двигатель - 3,0 кВт - Судовой двигатель

48. HZT023280010 - Вакуумный насос 25 MBA

6541458, 5900200, 6558400147, 5957600, 5980801, 6541673, 5979000, 5435181, 5451480, 6543469, 6543521, 5980914, 5981000, 6545873, 6545872, 6541672, 5979500, 5979600, 6542601, 6542586, 6541675, 5775500, 5973401, 6545363, 6543035, 5959902, 6542998, 6545393, 6541552, 5437623, 6540972, 6540973, 6543036, 5821700, 5433594, 6542305, 6545041, 5821000, 6542997, 6547089, 6547327, 6545537, 5490590, 5490587, 5450072, 5490580, 6541525, 6546852, 6545903, 6541709, 6541708, 6546255, 6542549, 6542827, 6543101, 6545725, 5437598, 5430612, 6541200, 5442101, 5824900, 6541003, 5980802, 6542958, 5435169, 6545052, 65433072, 5779210, 5780000, 5779400, 5435269, 6543003, 70701001, 5774002, 5774000, 5900204, 5435015, 5774901, 6542981, 6545051, 6542402, 6543002, 5481004, 6543072, 5445001, 6545828, 6540969, 5437666, 5913502, 5430595, 5979312, 6545901, 5490548, 6542451, 6542434, 6543229, 5470214, 6542983, 6542982, 5433215, 5432548